עגם תשלובת מפעלים

תשלובת המפעלים עגם מצויה בחזית התעשייה הישראלית ומציינת בגאווה יותר מ־50 שנות פעילות מוצלחת.

החברה מהווה חוד החנית ועמוד השדרה של התעשייה הישראלית על כל רבדיה, בארץ ובעולם.

את טביעת האיכות של עגם ניתן לראות כיום במגוון תחומים – תשתיות, כבישים, גשרים, רבי קומות, מנהרות, קונסטרוקציות כבדות, תעשיות ביטחוניות ועוד.

לתשלובת ארבעה מפעלי ייצור המשתרעים על שטח של 60,000 מ"ר ומרכזים את מיטב הטכנולוגיה המתקדמת.

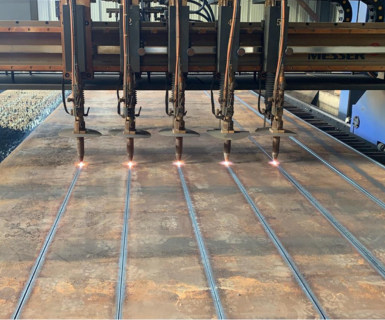

טכנולוגיה

מיטב הטכנולוגיה המתקדמת

שירותים

רמת השירות והאיכות הגבוהה ביותר ללקוחות הקבוצה בארץ ובעולם

פרויקטים

מפעלי ייצור ועיבוד מתכת בשטח כולל של 50,000 מ"ר

ניסיון

למעלה מ-50 שנות ניסיון

פתרונות מפתח לתעשייה

החברה מספקת ללקוחותיה מעטפת שירותים מלאה, החל מתכנון ועד ביצוע.

על פי צורכי הלקוח מבוצעים מגוון רחב של שירותים, ביניהם תבניות לבנייה מתועשת, פריטים ומכלולים לתעשיות הביטחוניות,

שירותי עיבוד, חיתוך בלייזר, חיתוך בפלזמה ולהבה,ניקוב, כיפוף, ערגול, ריתוך, צביעה של כל סוגי המתכות.